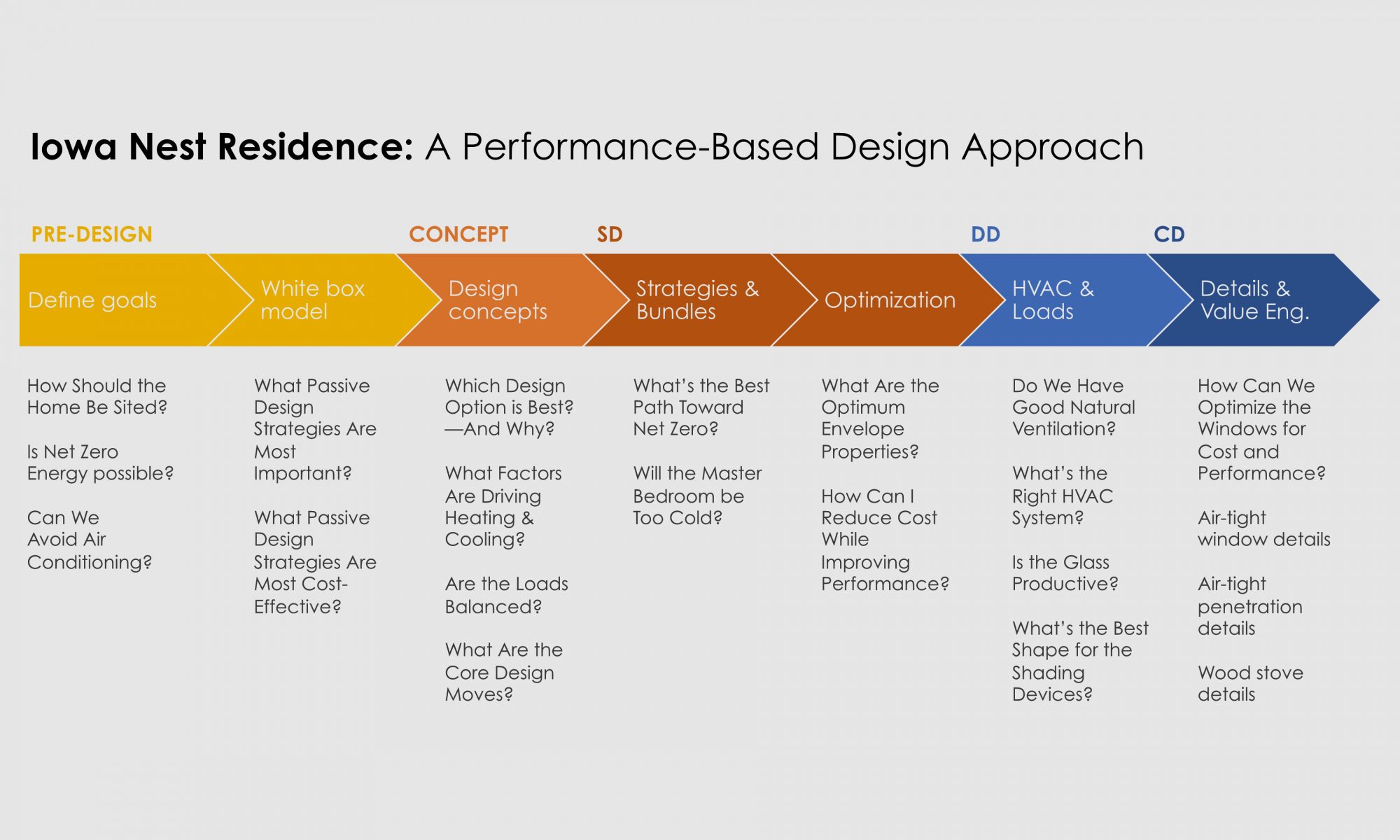

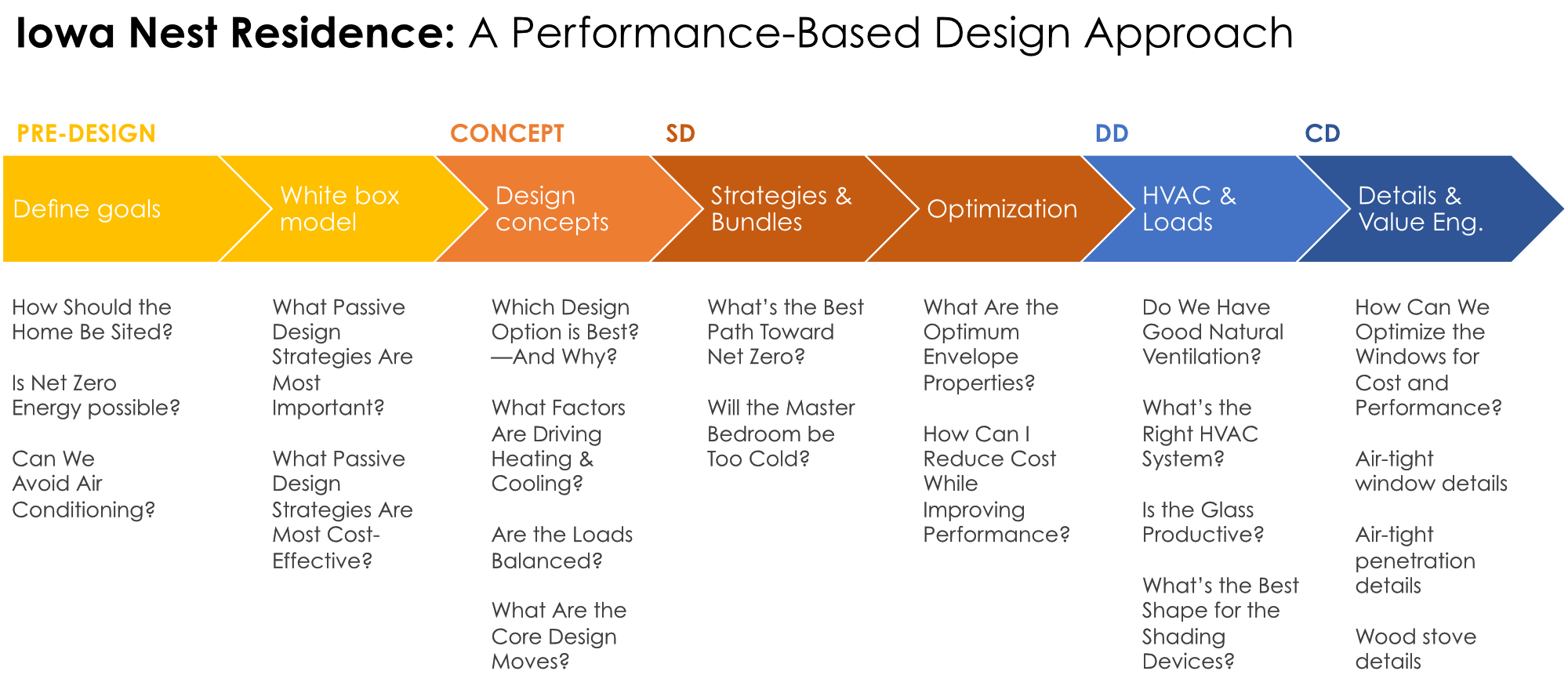

The design of this home was, in part, a test of a design process—of a philosophy of design—known as performance-based design. The central idea is that performance analysis (energy, daylight, and thermal comfort analysis, among others) has a central role to play in informing design decisions at every step of the process.

I believe that performance is a constraint that can inspire creativity—just as a deep understanding of the laws of gravity has led to the creation of some of history’s most inspiring structures—; and that rendering performance visible through simulation enables architects to engage with it and manipulate it as part of the creative process.

The design was also the test of a software: Sefaira, a tool purpose-built to enable performance-based design, which I utilized throughout the process. (Full disclosure: I helped to create Sefaira, and served as Product Manager and Director of Product Marketing during design and construction of this project. This home allowed me to put the tool through its paces.)

Below is an outline of the design process, with key design decisions and analyses that helped shape the design. Each item is framed as a question—because clearly articulating the problem the first step toward finding a solution.

Pre-Design

Even before putting pen to paper, pre-design studies can help to identify constraints and opportunities, discover the boundaries of the design problem, and set realistic goals and targets.

- How should the home be sited? The initial site visit looked into questions both poetic and pragmatic.

- What passive design strategies are most important? I utilized a simple box model and sensitivity analysis to identify strategies that should drive the design, based not only on climate but also on building type and site constraints.

- What passive strategies are most cost-effective? A simple cost overlay onto the sensitivity analysis clarifies the importance of low- and no-cost strategies.

- Is Net Zero Energy possible? Another simple box model, this one testing whether our goal was feasible, and roughly what it would take to get there. What R-values, how much thermal mass, how much glass, how much shading? These are key inputs to the design process.

- Can we avoid air conditioning? Another simple box text of a goal, this one whether no-AC is feasible in hot, humid Iowa summers—including in the context of a changing climate.

Concept Design

This stage is about exploration: testing numerous ideas, iterating, refining—finding out what works and what doesn’t. The key is to understand WHY certain designs do or don’t work, so we can learn and improve as we iterate. For many aspects of design, the WHY is self-evident; for daylight, energy & comfort, it requires a new way of thinking.

- Which design option is best?—and why? Fast, simple energy and daylight models for the purposes of comparing some early ideas—and what I got wrong when I did this analysis.

- What factors are driving heating & cooling? I used regression analysis on the design comparison above to try to tease out the factors that were having the biggest impact. (Spoiler: glazing ratios and envelope area.)

- Are the loads balanced? This was a simulation I should have done that this stage, because it would have saved a good bit of headache later on: Are the peak heating and peak cooling loads relatively constant, or are there “hot spots” and “cold spots” that will drive HVAC complexity or lead to thermal comfort issues?

- What are the core design moves? At this stage, I began to craft a “performance parti”—the most elemental design response to the lessons learned thus far. It began to establish (and unify) the architectural language, the material palette, and the passive design strategies.

Schematic Design

Once a concept is defined, schematic design fleshes it out further: the floorplan organization, construction, envelope assemblies, materials, and a first pass at HVAC systems. At this stage the analysis is less about broad-brush comparisons and begins to lean more toward optimization, albeit still at the whole-building level.

- What’s the best path toward Net Zero? Now that we have a building form, we can dial into the design in more detail. What’s the best combination of strategies to achieve our goal?

- What are the optimum envelope properties? As part of the prior analysis, I used Response Curves to find the optimum R-values and glazing properties for the design. I then began to translate these into actual assemblies and initial wall sections.

- Will the Master Bedroom be too cold? A quick study of the north-facing Master Bathroom to make sure I’m not creating a comfort or peak load problem—and equally quick iterations to see how I could improve performance.

- How can I reduce cost while improving performance? The initial schematic design was nearly 2x over-budget. The re-design was all about reducing cost without compromising performance. In the end, we were actually able to improve performance by ~10%. Here’s how.

Design Development

With the basics of the design locked down, design development is about refining the design and coordinating various systems. Many of the analyses at this stage have to do with specific areas or aspects of the design.

- Do we have good natural ventilation? Optimizing “free area” of window opening for natural ventilation.

- What’s the right mechanical system? We evaluated several options for mechanical systems, looking at tradeoffs among performance, cost, comfort, maintenance, and additional on-site renewable generation.

- Is the glass productive? In a well-insulated home in a cold climate, glass is a liability, and should be used “productively” — to capture daylight, direct sunlight, views, or ideally all of the above. Using daylighting analysis and sun studies, I optimize window area and daylighting strategies.

- What’s the optimum shape for the shading devices? Shading is critically important in this project: we want as much sun as possible when heat is needed, and as little as possible when it’s not. Here’s how I utilized sun studies and Direct Sunlight analysis to optimize the shading elements.

Construction Documents

At this stage we dive deep into details and the affordances of specific products. For this project, much of the air-tightness was in the details. As we got feedback from manufacturers and products reps, we continued to cost-optimize and refine the design.

- How can we optimize the window package for cost and performance? With help with from the team at Zola Windows, we learned what factors drove window costs and worked to bring the windows in budget. Quick daylight studies helped to inform revisions.

- Daylight study: 2016-0402 window options

- How can we achieve air-tight windows? Air-tightness was a key part of achieving the target performance—and windows were among the most important elements to get right. Here are our details, in theory and in practice.

- How can we achieve air-tight penetrations? Lots of stuff has to come through the wall and roof. Here are our details.

- How do we (safely) detail a wood stove? Putting a combustion appliance in an air-tight house requires careful consideration to a number of factors. Here’s our approach.

- Should we really build without AC? Leaning on an interdisciplinary team to understand the risks of building without AC, and ways to future proof the design.

And from there—we go on to construction!